June 20, 2024

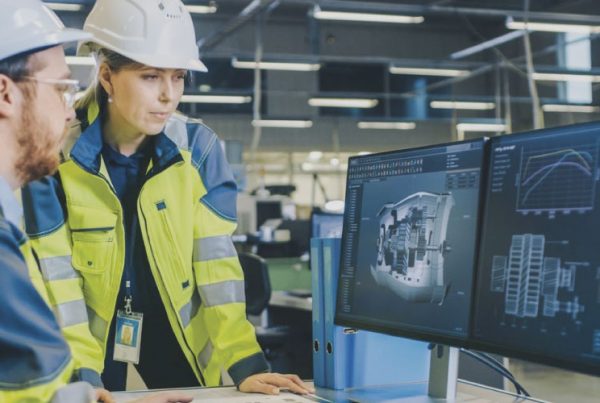

Transforming your maintenance program requires adopting essential best practices that drive efficiency and reliability. Start by implementing a proactive maintenance strategy, utilizing predictive analytics to foresee potential issues before they escalate.

Transforming your maintenance program requires adopting essential best practices that drive efficiency and reliability. Start by implementing a proactive maintenance strategy, utilizing predictive analytics to foresee potential issues before they escalate.

Regularly train your maintenance team to ensure they are equipped with the latest knowledge and skills. Leverage technology such as IoT sensors and maintenance management software to monitor asset health in real-time. Establish a robust data management system to track performance metrics and inform decision-making. By focusing on these best practices, you can significantly reduce downtime, lower maintenance costs, and extend the life of your assets.

Assess Current Strategy: Begin by understanding where your maintenance practices currently stand. Analyze metrics like planned versus reactive maintenance to establish a performance baseline. Evaluate your ability to capture and analyze asset data effectively, as this forms the foundation for informed decision-making and process improvement.

Identify Strategic Assets: Not all assets require predictive maintenance. Focus on identifying critical assets that directly impact revenue and production throughput. For instance, high-throughput production lines may require different maintenance priorities compared to assets with lower production demands.

Determine Failure Indicators: Predicting failures involves identifying specific indicators for each asset type and environment. Historical performance data and failure studies help pinpoint trends and potential issues early on. Be cautious of false positives by validating indicators against operational context.

Implement Real-Time Actions: Timely action based on real-time data is crucial for effective predictive maintenance. Automate data analysis processes to swiftly identify anomalies and issues. This proactive approach minimizes downtime and optimizes maintenance efforts, freeing up resources for more strategic tasks.

Measure and Refine: Continuously monitor and refine your maintenance program. Measure the impact of enhancements using key metrics such as Overall Equipment Effectiveness (OEE), Mean Time Between Failures (MTBF), and energy efficiency. Adapt and scale your strategies based on performance feedback to drive continuous improvement across your operations.

Optimize your asset management practices to achieve superior efficiency, reliability, and cost-effectiveness! By embracing proactive maintenance strategies and leveraging advanced technologies such as IoT sensors and predictive analytics, you can anticipate issues before they occur and minimize downtime. These efforts ultimately drive greater value for your organization.